#completenessCheck #assemblyLines #qualityControl #machineVision

Assembly parts

SanitAry

Centimeters

identification & Completeness check

2D cameras

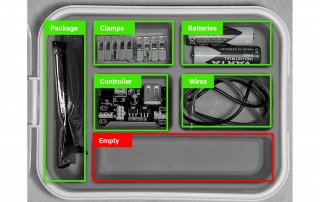

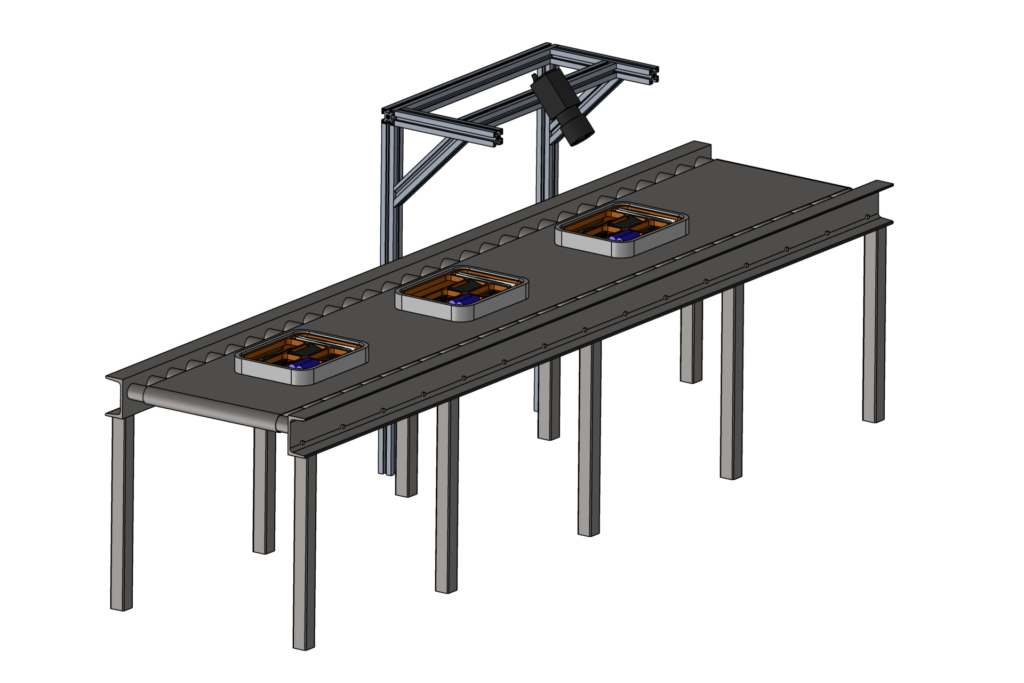

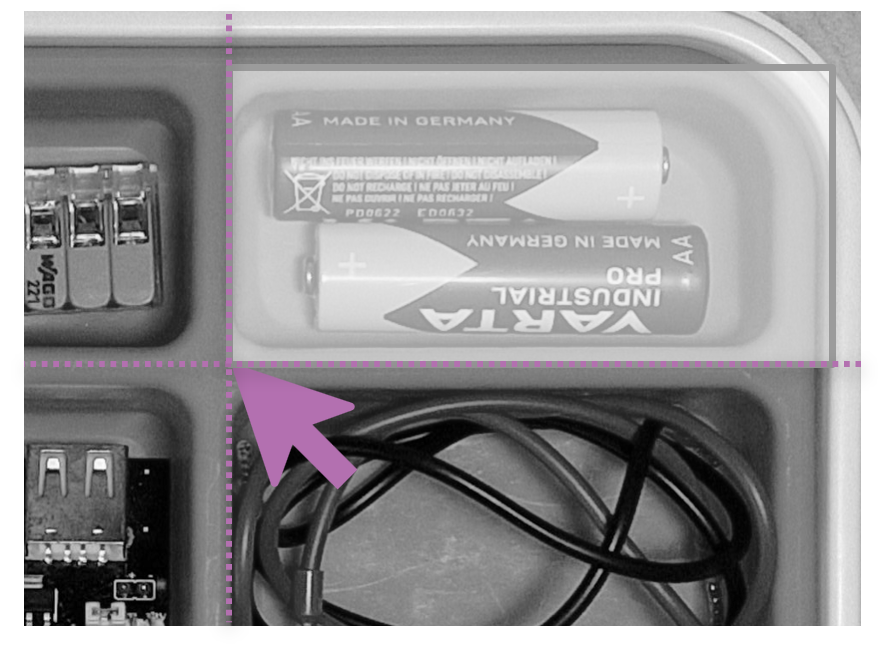

In collaboration with our customer, we developed an automated solution to ensure the completeness of assembly sets. This real-time system uses advanced AI algorithms to detect missing parts during the compilation process. It is designed for ease of use by factory personnel, allowing simple and independent adjustments. A camera monitors the station, capturing all parts and displaying any missing components on a screen to inform the operator. This data can be transmitted to production and quality systems. New configurations are easily set up through a drag-and-drop interface, with existing plant control interfaces loading the correct settings for new orders. By integrating this solution, we enhance efficiency and accuracy, preventing costly and frustrating issues with incomplete assembly sets for customers.

Requirement

Incomplete assembly sets at the customer’s premises are annoying and expensive. A system based on modern AI algorithms recognizes incomplete sets in real time. This ensures that no parts are overlooked when compiling individual parts into assembly sets.

Challenges

The biggest challenge for preML was the usability requirements for the plant personnel. The fact that there is a variety of assembly sets and a variety of components meant that it had to be possible to make settings on the system independently and easily.

Hardware

A camera is used to monitor the station and record all parts. The system runs on the customer’s network and the calculation is performed on the edge device. Missing parts are displayed on a screen to inform the employee. Information can be transferred to the production and quality system.

Software

The software is based on a simple object recognition algorithm. The employee can independently specify the positions in a configuration mode and adjust them at any time. Parts can be easily marked and positioned in the configurator using drag and drop. Existing interfaces with the system controller load the correct configuration for new orders.