![BMBF_CMYK_Gef_M [Konvertiert]](https://www.preml.io/wp-content/uploads/2023/01/BMBF_gefoerdert_2017_en-300x206.jpg)

AI-enabled monitoring for the production of precast concrete elements

Artificial Intelligence meets the precast concrete industry! In the following you will find information about the research project KI4PRECAST within the BMBF Research Call “KI4KMU”.

Timeline: 10/2022 – 12/2024

Discover the results of our research project in three concise videos (available in German).

This research project aims to bring disruptive change in the manufacturing process of pre-cast concrete elements that are used in the construction of large infrastructure structures, housing and industrial building by using data-based artificial intelligence. Focus of the project are three aims , first, developing an early warning system which can optimize production time, second, avoid cracking during the curing process and third, eliminate wastage of concrete during production of prefabricated concrete elements.

The warning system will be based on an AI based diagnostic and prognosis tool. This tool would leverage information from experiments, real field data by corporations as well as high fidelity multi-scale and multi-physics models. The developed tool should predict in real time internal states of precast elements (temperature, relative humidity, internal stresses, and strength development) considering the ambient conditions within the curing chamber. The developed tool will be extensively tested in practical conditions by collaboration with industrial cooperation partners.

Consortium

The project consortium consists of preML GmbH specializing in artificial intelligence (AI) applications in the manufacturing industry and the Institute for Concrete Structures and Building Materials Technology (IMB/MPA) of the Karlsruhe Institute of Technology (KIT) that is a leading research facility in building material and concrete technology.

#concreteProduction #concreteScience #concreteMixtureDesign #machineLearning #strengthDevelopmentPrediction

related blog posts

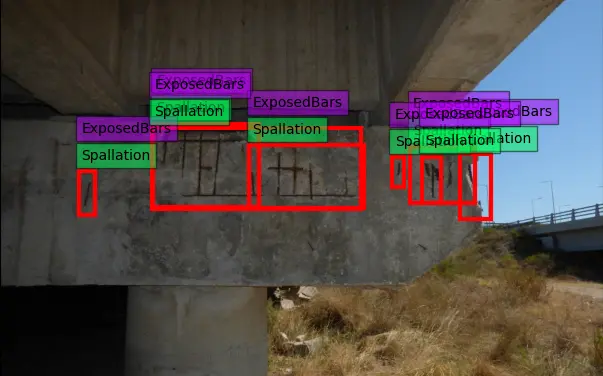

Visual Inspection of Concrete Bridges with AI

While usually working with precasted concrete elements, we joined forces [...]