#surfaceCheck #wetConcrete #defectDetection #qualityControl

WET Concrete

Construction

2 x 3 meter

Surface Quality

2D cameras

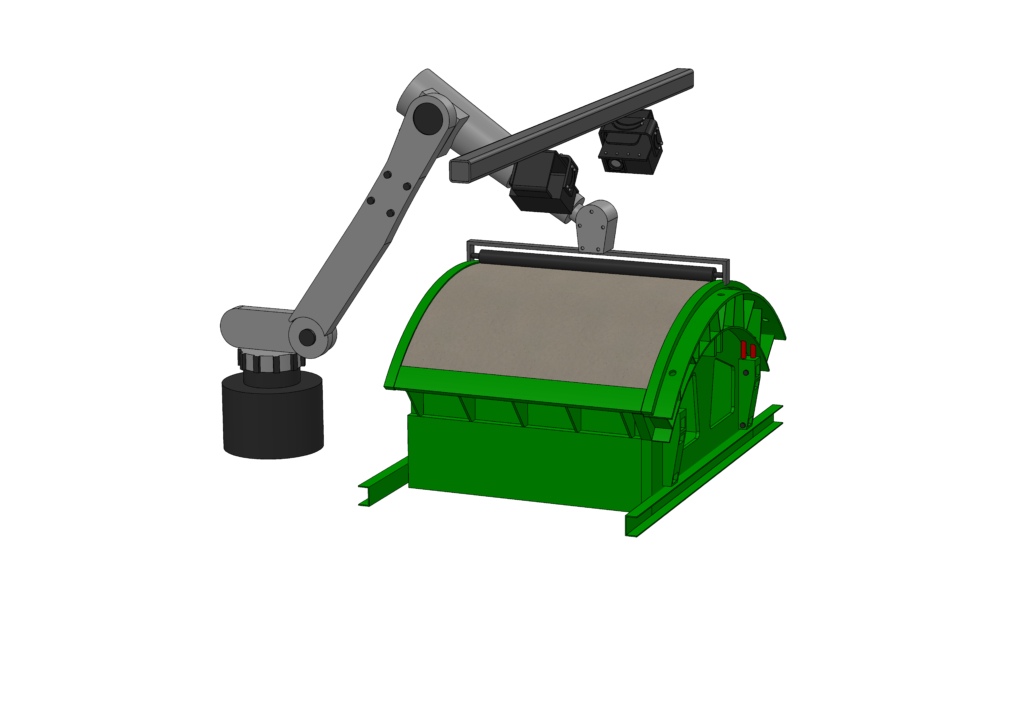

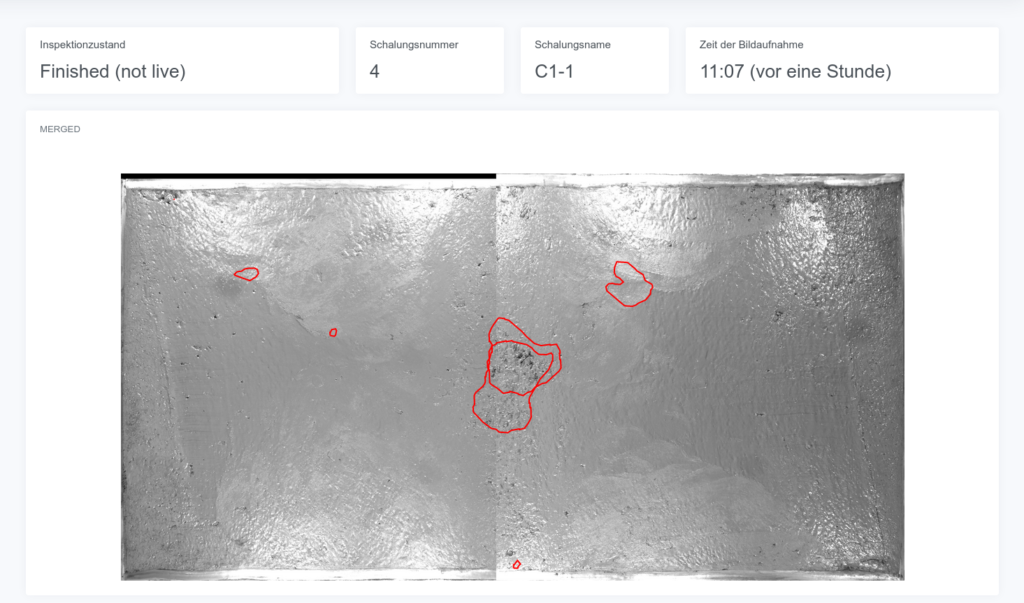

Based on the requirements of one of our customers clients in Switzerland, we developed an automated solution for inspecting the wet surface of tunnel segments at the end of the construction line. This system investigates the surface of the concrete for defects, such as holes, material nests and visual consistency. The system’s advanced sensors and imaging technology ensure that each segment meets stringent quality standards before it is used.

Requirement

Modern traffic tunnels are often constructed using tunnel boring machines and the segmental lining method, which involves lining the tunnel with precast concrete segments. These segments are produced using standard precast concrete procedures. In this particular project, a robot smoothens the wet concrete surface, which is then inspected for quality. If flaws are detected, corrective actions are proposed to ensure high standards.

Challenges

The system overcame several challenges, including the large size of the concrete segments and the variability of concrete as a natural material, which changes with seasons and input materials. Additionally, the subjectivity of quality assessments adds complexity to ensuring consistent standards.

Hardware

In cooperation with our customer, it was possible to design a hardware concept that works stably in the tunnel environment and is particularly protected against contamination. The final concept consists of two high-resolution 2D cameras that inspect the surface of the object. The data is processed on an edge device, which has advantages in terms of real-time requirements and reduced bandwidth requirements. Signalling and identification is realized using an existing OPC UA infrastructure at the production site.

Software

Various machine learning algorithms were trained to detect reliable defects. This is based on the in-house CVC Inspect infrastructure for machine learning pipelines. The models were implemented using the latest machine learning technologies and are defined for the detection of the defect classes. The frontend is realized in the CVC Control Dashboard allowing employees in the prodcution line as well as quality managers easy access to the system. Data and results are also forwarded into the Segment Documentation System (SDS) by VMT GmbH.