Author

David Fehrenbach

David is Managing Director of preML and writes about technology and business-related topics in computer vision and machine learning.

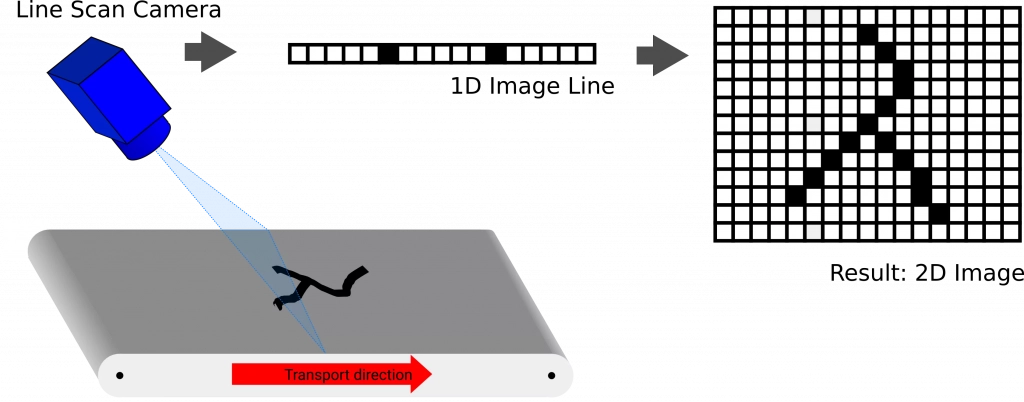

The line scan camera is a type of camera that has only one line of pixels. In contrast, regular cameras have a two-dimensional sensor, which exposes several lines simultaneously. In this blog post we will give you some background information about the line scan camera.

Image 1: Illustration of the functionality of a line scan camera.

Image Aquisition and Positioning

In order to obtain a two-dimensional image of a surface with a line scan camera, which can then be evaluated later for analysis, several lines must be recorded one after the other while the camera moves relative to the object. This can be implemented in different ways:

- The camera is fixed above a belt conveyor and the object is conveyed past the camera.

- The camera is moved along a stationary object with a linear unit or a robot arm.

- The object is moved along the camera by a robot.

- A cylindrical object is rotated using a rotary unit while the camera captures the mantle surface

A clock generator is necessary to trigger the recording of the individual lines.

Advantages and Challenges

A major advantage of using line scan cameras is that they have a very high clock rate (10 – 400 kHz). This allows fast moving objects to be recorded without motion blur. This is essential for continuously moving objects, e.g. non-stop belt conveyors with individual objects, film production or printing machines. In addition, line scan cameras have a high resolution. While current 2D cameras have a resolution of up to 5,000 px in one dimension, line scan cameras exist with up to 16,000 px.

The challenge of using line scan cameras is that the short exposure time requires much brighter lighting. In addition, the traversing unit and clock must have high accuracy in order to trigger the camera several thousand times per second at equidistant points.

If you think you have a applicaiton for a visual quality inspection system which can be done by using a line scan camera, feel free to request a free of charge feasibility check by pressing the botton above!

Cheers!

David

Contact us at contact@preml.io or connect with me on LinkedIn

Autor

David Fehrenbach

David is Managing Director of preML and writes about technology and business-related topics in computer vision and machine learning.