Author

David Fehrenbach

David is Managing Director of preML and writes about technology and business-related topics in computer vision and machine learning.

One of our most interesting projects is the AI-based quality assurance of tunnel segments. Together with our customer VMT GmbH we were able to publish a paper of this system, which was presented at the World Tunnel Congress 2023 in Athens! In the following, we give some insights into the publication. Big thanks to everyone participating in the project!

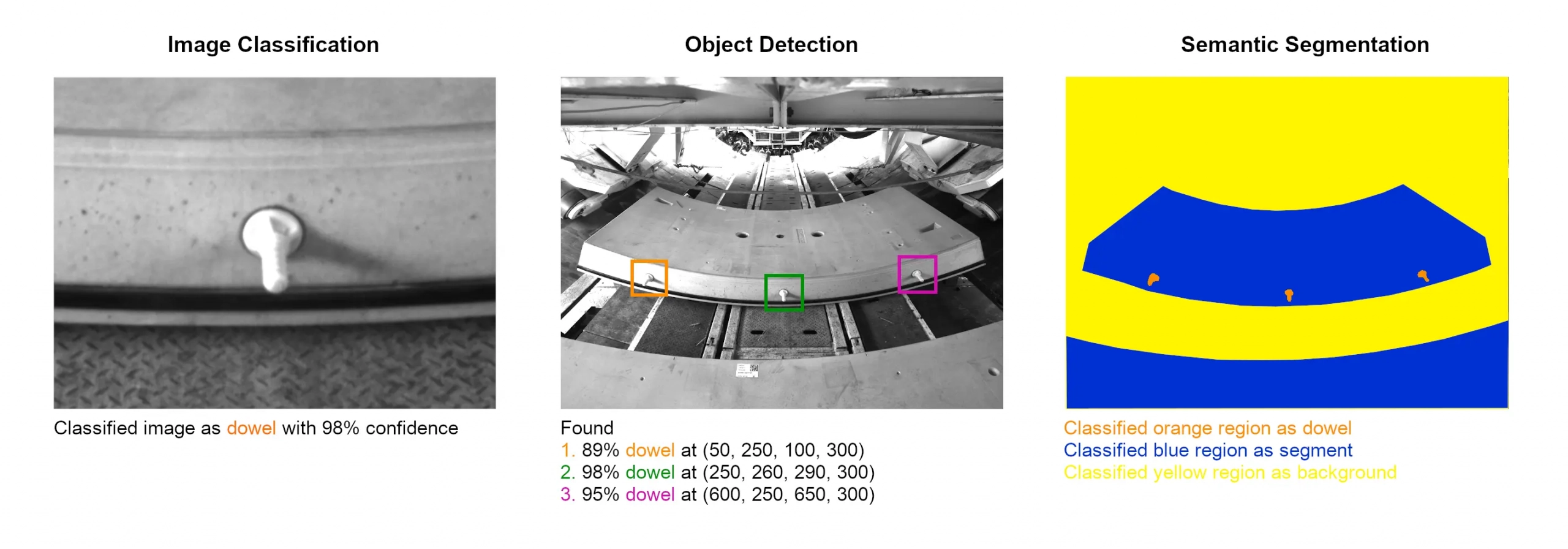

Image 1: Different Computer Vision tasks performed on a tunnel segment.

The official summary (Abstract)

Tunnel segments for large traffic tunnels are subject to the highest quality standards in the concrete precast industry. Given their large dimensions, it is inevitable that various defects occur during production or transportation. This paper presents a novel approach to the quality control of the segments at the latest possible location inside the tunnel boring machine (TBM) before the final ring erection. An artificial intelligence (AI) based computer vision (CV) software was developed to check images of the segments, with the images being collected by four cameras inside the TBM. The system “segment check” is able to detect missing dowels and misplaced seals, as well as cracks and spallings. By adopting various AI-based image processing modules, this work is on the forefront of applying AI in the tunnelling world. Results show high accuracy for a 3D pose estimation network of the segment, as well as for the segmentation and classification networks which are used to perform the quality inspection.

Read the paper in Bullet Points:

- A novel approach called “segment check” using artificial intelligence (AI) and computer vision (CV) software was developed to inspect tunnel segments for defects in the tunnel boring machine (TBM) before final ring erection.

- The system demonstrated high accuracy in detecting missing dowels, misplaced seals, cracks, and spallings in tunnel segments.

- The use of AI-based image processing modules, such as 3D pose estimation, segmentation, and classification networks, enabled accurate quality inspection of the segments.

- The imaging system was designed with robust cameras placed optimally to avoid dust and oil in the TBM environment, and a custom case was used to protect the cameras from vibrations.

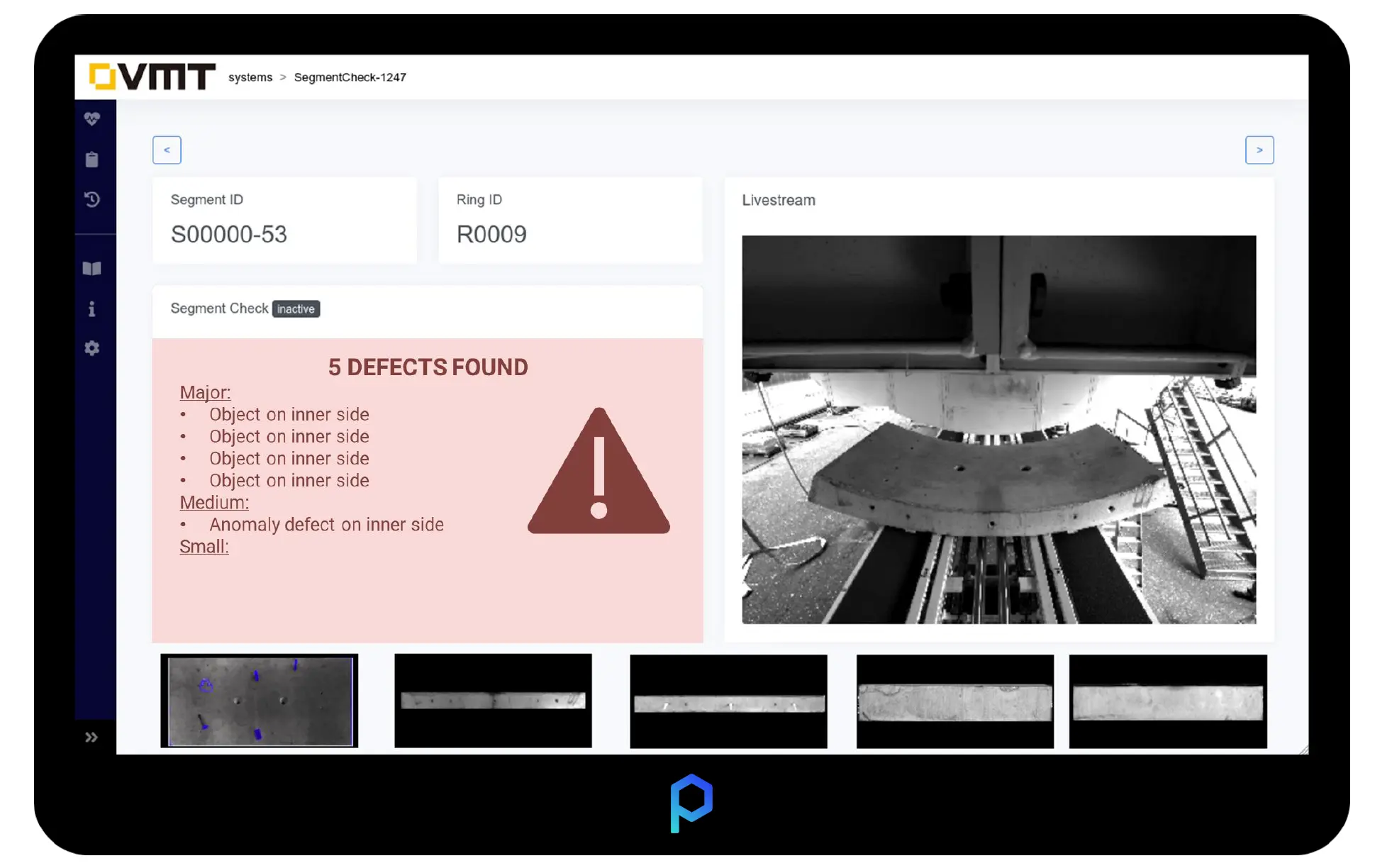

- A user-friendly dashboard was created to provide real-time visualizations of the system state, detection results, and access to analytics and historical data, enabling effective human-machine interaction and documentation.

Image 2: Dashboard visualisation for the operator of a tunnel boring machine

How to learn more about it?

- We will hopefully give you more information soon in our webpage

- You can accesss a small management preview of segment check at the VMT Homepage via this link

- You can access the full paper from the publishers website, or you can also click the button below and request it from us:

We will keep publishing about our work and doing, because we believe in a open and communicative science community!

Cheers!

David

Contact us at contact@preml.io or connect with me on LinkedIn

Autor

David Fehrenbach

David is Managing Director of preML and writes about technology and business-related topics in computer vision and machine learning.